Cartridge Filters: Spun Bonded

Spun Bonded Cartridge Filters

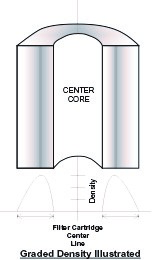

Spun Bonded Cartridge filters are manufactured through a process that thermally bonds pure Polypropylene microfibers with lower density at the outside surface and progressively higher density toward the center. This is Graded Density. This fully automated manufacturing process assures consistent quality, filter to filter, year in and year out.

Spun Bonded Cartridges can be used either as a pre-filter or final filter for industrial, chemical process, pharmaceutical, food/beverage, cosmetics, water and other applications.

You can download a PDF of this page here: Spun Bonded Cartridge Filters PDF

What Spun Bonded Cartridge Offers:

- Superior capacity – particles are trapped throughout the entire cross section

- Fewer filter changeouts-no surface blinding

- High flow rates with low pressure drop throughout the micron range

- Longer service life

- Reduced fiber migration

- Excellent end sealing

- No chemical additives to contaminate filtrate

- Broad chemical compatibility

- No extractables

- Easy disposal-Incinerates to non-volatile trace ash

- Surfactant Free

Links:

- Cartridge Filters/Industrial Cartridge Filters

- Stringwound Cartridge Filters

- Spun Bonded Cartridge Filters

- Carbon Cartridge Filters

- Cartridge Filter Housings – Stainless Steel

- Cartridge Filter Housings – Plastic

- Capsule Filters

- DE Filter or Lenticular Filter

- Pleated Cartridge Filters – High Purity

- Pleated Cartridge Filters Light Industrial

- Bag Size Pleated Cartridges

Call us at 603-434-9577 or contact us for more information.