Stringwound Cartridge Filters

Stringwound Cartridge Filters

Stringwound Cartridge Filters at their finer micron ratings rely mostly on Van Der Walls or attractive forces for their small particle capture. With this in mind, when using depth Stringwound Cartridge Filters or any depth filter, flow is a critical factor in the filter’s performance.

A TIE or Ten Inch Equivalent is the way we normalize or standardize the operating parameters of Stringwound Cartridge Filters. With Stringwound Cartridge Filters, optimum dirt holding capacity and particle removals at the stated micron rating occur at flow rates between 2 and 3 Gallons Per Minute per TIE. Above that flow per TIE, you get reduced life and dirt holding capacity.

Other factors include not letting the dirty pressure drop exceed 15 to 20 PSI. Unloading of particles occur at higher pressures as flow forces overcome the Van Der Walls attractive forces.

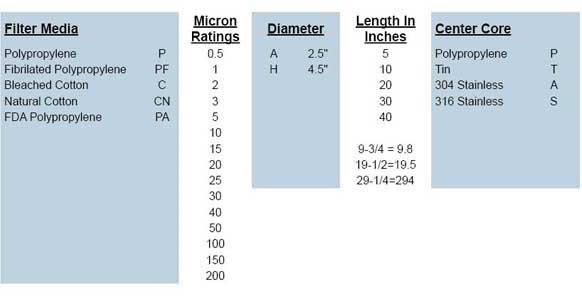

From the Chart we can build a part number using the following as an example: C5A10P

Bleached Cotton, 5 Micron, 10” Length, Polypropylene Center Core.

Typical Diameter is 2.5 inches which is represented by the A in the above part number example.

The H Diameter of 4.5 inches is the “Big Blue” housing diameter.

You can download a PDF of this page here: StringWound_Cartridge_Filters

Links:

- Cartridge Filters/Industrial Cartridge Filters

- Stringwound Cartridge Filters

- Spun Bonded Cartridge Filters

- Carbon Cartridge Filters

- Cartridge Filter Housings – Stainless Steel

- Cartridge Filter Housings – Plastic

- Capsule Filters

- DE Filter or Lenticular Filter

- Pleated Cartridge Filters – High Purity

- Pleated Cartridge Filters Light Industrial

- Bag Size Pleated Cartridges

Call us at 603-434-9577 or contact us for more information.