EDI-Electrodionization Water Systems

EDI-Electrodionization Water Systems

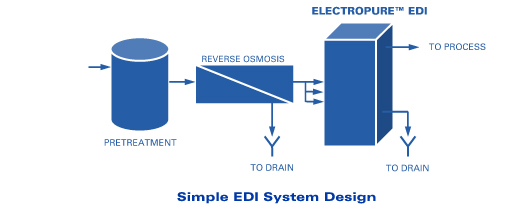

A simplified EDI process is shown above. EDI removes the remaining dissolved minerals (TDS) after Reverse Osmosis. EDI takes the place of the Ion Exchange step in many Electrodeionization System Designs.

Process of Electrodeionization

The Electropure™ EDI design combines two well-established water purification technologies—electrodialysis and ion-exchange resin deionization. Through this revolutionary technique, dissolved salts can be removed with low energy cost and without the need for chemical regeneration; the result is high-quality pure water of multi- MΩ.cm resistivity which can be produced continuously at substantial flow rates. Electropure’s EDI removes ions from water by forcing them out of the feed stream into adjacent streams via an electric potential. EDI is different from ED by using resins in the diluting chambers—the resins allow for more efficient migration of ions in very low conductivity water. The resins operate in steady state; they act not as an ion reservoir but as an ion conduit.

EDI Water System Applications

We utilize the Electropure EDI systems manufactured by Snowpure.

Pharmaceutical & Laboratory

Our EDI products are integral components in installations that require compliance with the USP (US Pharmacopoeia). Electrodeionization (EDI) is used to replace or traditional non-membrane processes like resin deionization.

Specifically in a USP Purified Water System, after Reverse Osmosis, EDI will take the water up to the required Conductivity while maintaining the TOC USP requirements.

Power Generation

Electrodeionization (EDI) in Power Generation is used to replace and/or augment the polishing TDS removal step Power Plant Requirements Combined-cycle power plants and all high-pressure steam turbines require high-pressure water, free of silica. SnowPure’s EDI and GTM products replace traditional chemical-based resin systems, making an all-membrane process.

Semiconductor and Electronics

High-technology industries use EDI – Electrodeionization in making the ultrapure water utilized in their manufacturing. EDI Water Systems for the semiconductor, electronics, solar panel, hard disk drive, glass lens, and flat panel display industries are typical examples. These industries often require “ppt” (part-per-trillion) level impurities.